Corn starch process is a process of physical separation. The purpose to produce corn starch is to separate the non-starch substances such as protein, fiber, fat and inorganic salts and other substances existed in corn. It’s based on starch properties. Starch is undissolved in cool water. Density of starch is bigger than that of water.

In the process selection, the corn starch processing mainly utilizes wet processing which main separation and twele hrydrocyclone counter current washing. The production process is fully enclosed in themal circulation. The process water is basically recycled. The process technology is mature, reliable and stable in quality.

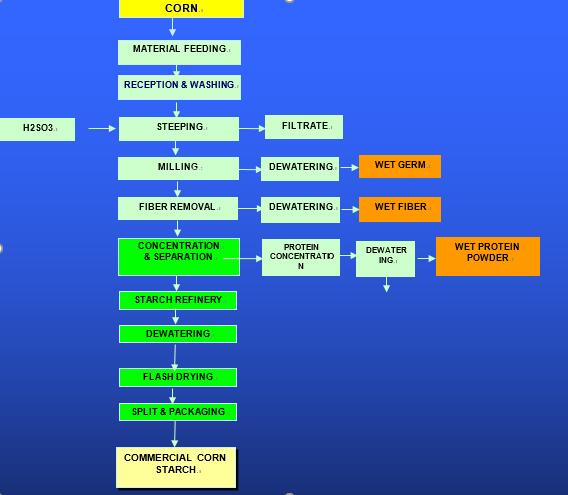

Process Flow Chart

Technical description

1). Steeping

The cleaned corn is feeded into the steeping tanks.

The target of steeping is to separate the soluble matters, reduce the mechanical strength of corn particle, in order to make the subsequent mechanical separation of corn particle easier.

The corn is steeped in the warm process water for a certain time, during steeping, the corn particle will absorb water and expand. Add sulphurous acid in the process water to accelerate penetration and passivate the germ and anticorrosive.

A complete steeping process in one tank include four stages:

Put the steeping solution and corn into the steeping tank; Steep corn; Discharge steeping solution; Discharge the steeped corn.

During the steeping process, the steeping water circulates through the steeping tank. The steeping tank can be heated by the connected heater. The steeped corn will be pumped into the crusher together with the transporting water, and be sent to the bend sieve to remove parts of the transporting water. The transporting water can be recycled many times. Before the steeping unit, the installed destoner will remove the mineral impurities.

2). Grinding, germ separation and fibre separation

The steeped corn is feeded into the first crusher through feed hopper, the germ can be separated after crushing. A portion of starch will be released. Grinding includes two steps: first crusher and second crusher. After each grinding step, there are two-stage degerming cyclones for separating germ. The bottom flow of 1st degerming cyclone flows into the bend sieve depending on gravity, the overflow flows into the second crusher. The overflow of the 1st degerming cyclone firstly separate the germ, the overflow contains some starch, in order to recover these starch, use a three-stage bend sieve with process water to wash away the free starch. The washed germ is dewatered in a horizontal spiral centrifuge. The bottom flow of 2nd degerming cyclone flow into bend sieve, the starch milk will be extracted ( the screened starch ), the overflow the bend sieve will flow into the grinding mill.The bottom flow of the crusher is pumped into a multistage bend sieve system. The bottom flow of the 1st stage bend sieve is the remainings of the screened starch. The overflow containing fibres will be pumped into the subsequent stages and be washed to recover the remaining starch. The fibres from the final stage bend sieve contains much water, it must be dewatered. The dewatered fibres is transported into the feed hopper.

The starch milk contains starch, gluten and water, perhaps few fine fibre of impurities. Remove the impurities by a twelve-stage cyclone.

3). Starch and protein separation, gluten concentration and dewatering, starch washing

After separating the fibres skin residues, the starch slurry is feeded into centrifuge or cyclone. The overflow of the cyclone contains soluble matters and fine fibres, they can be used as steeping water. Separate the starch and protein with all centrifuges or the primary centrifuges. The starch particles flow from the bottom flow outlet.

The overflow of the primary centrifuge contains few protein. The gluten, water and protein particles are concentrated by centrifuge, then recovered by vacuum filter dewatering. The overflow of the cyclone can be used as process water. The starch separated by the primary centrifuge is washed and refined by multistage cyclone, the wash water comes from the users water supply system. Before wash water is feeded into the multiplestage cyclone, the foreign impurities will be removed by desander and filtrating apparatus, also should be heated.

The starch milk refined by multiplestage cyclone flow into the starch milk tank, then pumped to the dewatering, drying and packing units

online service

online serviceScan to wechat :