Product Advantages

1.Combining the mature European technologies and domestic production in high standard, makes our system of the best performance-price ratio.

2.Fully closed and modular structure makes compact layout, resulting in a sharp reduction of installation time.

3.Steady running control system range from fully automatic to manual, catering to customers’ needs for various systems.

4.By utilizing 3D design software, detailed drawings can be provided for customers’ facilitated installations.

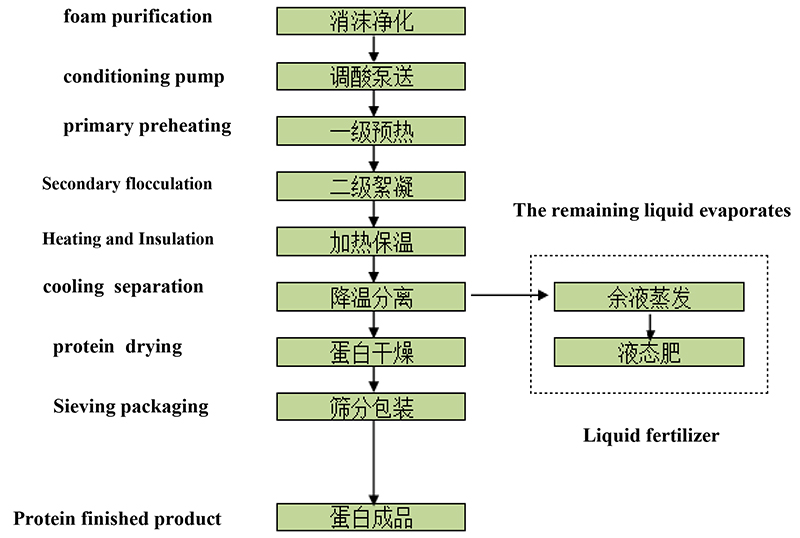

Process flow

Process Description

1. Raw material receiving unit

The raw material of the protein production line is the juice discharged from the starch production line, which is generally transported to the protein workshop through the centrifugal pump of the starch workshop.

2. Cyclone Screening Unit

The design of the cyclone screening part is mainly to remove the small granular starch and fibers contained in the juice, avoid affecting the flocculation of the protein in the later stage, and increase the protein content. The cyclone screening unit can be selected according to the requirements of the market situation on the protein content. When the market does not require high protein content, the cyclone screening unit may not be used. If the protein content requirements are high, a cyclone screening unit should be equipped. The main process is as follows: the juice from the starch workshop first enters the three-stage cyclone to remove the small starch particles in the underflow, and the overflowing juice enters the defoaming tank for defoaming.

3. Defoaming purification unit

The juice water after cyclone separation enters the defoaming tank along the tangential direction, and is defoamed by the three-layer spray defoaming device designed in the tank, and then enters the heating flocculation unit; the excess foam in the upper part of the tank is disposed in the defoaming unit. The defoamer and defoaming fan on the upper part of the tank are eliminated.

4. Heating the flocculation unit

After the juice is defoamed by the defoaming tank, it is pumped to two sets of spiral plate heat exchangers for heat exchange by high pressure pump. One of the first-stage spiral plate heat exchangers is used for switching, and the second-stage spiral plate heat exchangers are used for two separate sets. Switch to use.

After the juice is initially heated by the two-stage spiral plate heat exchanger, it is sprayed with steam by the steam injector to be heated again, and then passes through the heat preservation flocculator, so that the protein in the juice is continuously flocculated and deposited in the coil of the heat preservation flocculator. Due to the high temperature of the juice coming out of the thermal insulation flocculator, in order to save energy and reduce consumption, the juice will be heat-exchanged by the secondary spiral plate before entering the separation and dehydration unit.

5. Separation and dehydration unit

The protein in the juice is flocculated and precipitated by thermal insulation, and then heat-exchanged by the secondary spiral plate heat exchanger, and then enters the decanter centrifuge for dehydration, and separates the wet protein in the solid phase and the waste liquid in the liquid phase. The wet protein enters after being screwed. The flash drying unit is used for drying, and the waste liquid will enter the primary spiral plate heat exchanger for primary heat exchange due to the high remaining temperature.

The solid phase protein dehydrated by the decanter centrifuge falls into the horizontal screw conveyor from the solid phase outlet of the decanter centrifuge, and is collected by the screw conveyor before being transported to the inclined screw conveyor.

6. Flash drying unit

The wet protein is transported to the receiving hopper of the flashing main machine through the inclined screw, and the material is further broken up by the crushing device in the hopper and then transported to the inside of the flashing main machine, where it is mixed with the hot air heated by the air filter, blower and heat exchanger. It is fully mixed and heated inside the flashing machine to dry the water contained in the protein. At the same time, the drying pipe that enters the front of the fan from the tangential direction is unscrewed from the upper part of the flashing machine, and then enters the primary and secondary cyclones after being accelerated by the fan. The separator collects the protein powder, sieves and packs it, and discharges the tail wind.

7. In-line cleaning unit

The online cleaning unit is mainly used to clean the equipment and pipelines that need to be cleaned in the system. The online cleaning system is mainly composed of an acid tank, an alkali tank, a chemical pump, a CIP tank, a process water tank and a process water pump. The clean water pipe from the protein workshop in the factory area is connected to the CIP tank and the process water tank. The CIP tank can be cleaned by adding acid or lye through the chemical pump to cooperate with the system for cleaning. In order to ensure the cleaning effect, the tank is equipped with immersion steam heating The heater is used to heat up. Then, the cleaning water in the CIP tank or the process water tank is pumped into the system through the process water pump for cleaning the defoaming tank and the spiral plate heat exchanger.

online service

online serviceScan to wechat :