Product Advantages

1.Combining the mature European technologies and domestic production in high standard, makes our system of the best performance-price ratio.

2.Fully closed and modular structure makes compact layout, resulting in a sharp reduction of installation time.

3.Steady running control system range from fully automatic to manual, catering to customers’ needs for various systems.

4.By utilizing 3D design software, detailed drawings can be provided for customers’ facilitated installations.

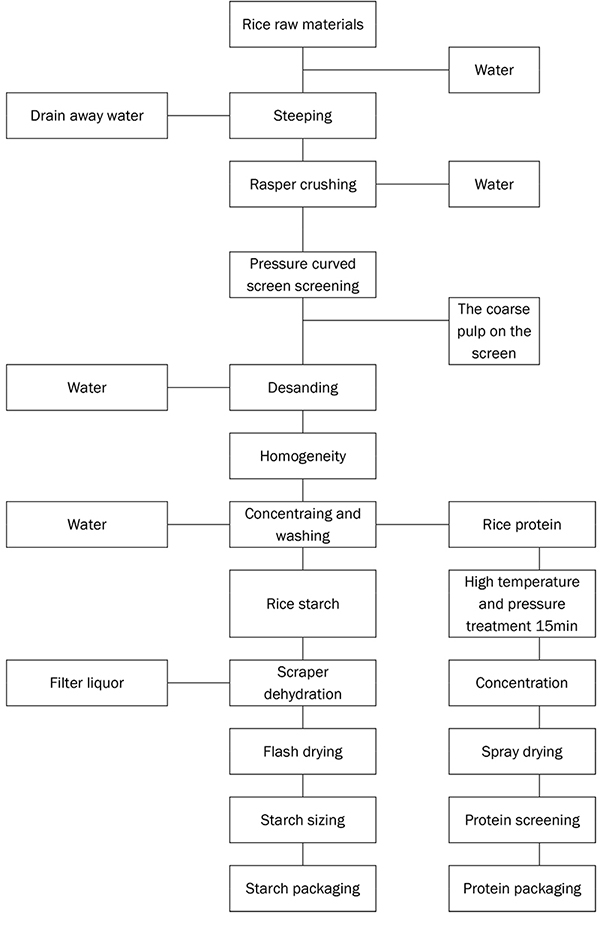

System Flow Chart

Technical description

1. Raw materials are an important part of rice protein and rice starch processing. Purchasing raw materials with high active ingredients can ensure the extraction rate of protein and starch. The less impurities in the rice, it has a good protective effect on the production line equipment and prolongs the service life of the equipment. Improve equipment utilization efficiency and ensure higher product quality.

2. The purchased rice raw materials are temporarily stored in the raw material warehouse after passing the inspection of the quality inspection department. When processing, drag the raw materials to the feeding area, lift the rice into the soaking tank with a bucket elevator after unpacking, add a certain amount of water, and soak the rice for a certain period of time as required. After the soaking is completed, the rice directly enters the needle mill through the flow pipe at the bottom of the soaking tank, and the rice is wet-pulverized, and a certain amount of process water is added during the grinding process.

3. The milled rice slurry directly enters the rice slurry temporary storage tank with a stirrer. A slurry pump is installed at the bottom of the tank, and the rice slurry is pumped into the pressure curved screen through the slurry pump.

4. The ground rice slurry is pumped into the pressure curved screen by the pump, and the coarse rice in the rice slurry is separated. The rice slurry is de-sanded by pumping into the desander to remove the sand and other particles with heavier specific gravity contained in the rice slurry. Coarse particles such as sand are removed from the emulsion. The desander includes a ceramic cyclone, a sand collecting tank, a manual sand discharge valve and a backflush water device. Backwash water avoids the loss of starch during sand removal. The emulsion after sand removal enters the homogenization unit, and is homogenized by a homogenizer, so that most of the combined starch and protein are separated repeatedly, so as to improve the extraction rate and purity of protein and starch in subsequent processing.

5. After the above process, the rice cells can be fully broken, and the protein and starch in the cells can be fully released, especially the combined rice and protein molecules can be well separated after homogenization treatment, which is the separation of the two. Provide better conditions to ensure their respective purity.

6. The homogenized rice slurry is directly passed through a 12-stage cyclone for separation, concentration and washing. The cyclone group is mainly composed of a concentration cyclone, a recovery cyclone and a washing cyclone. The powdered milk with a certain concentration and flow is pumped into the concentration cyclone to concentrate and separate the protein and starch, and the light phase protein enters the recovery cyclone to recover the smaller granules of starch entrained in the protein to ensure the cyclone station. The starch content in the overflow light phase is controlled within the required range to maximize the protein content in the protein product. The starch in the heavy phase enters the following nine-stage cyclone to wash the starch, and washes off a small amount of protein contained in the starch, which has achieved the purpose of purifying the starch. The washing water enters from the last stage of the cyclone station, and gradually replaces other impurities such as protein in the starch milk by means of countercurrent washing.

7. The protein from the cyclone station enters the protein temporary storage tank, and the protein solution is sent to the disc centrifuge by the pump, and the protein is concentrated by the disc centrifuge. The concentrated protein is pumped into the sterilization tank by the screw pump to sterilize the protein, and the sterilized protein enters the spray drying tower to dry the rice protein.

8. Due to the high moisture content of the heavy-phase starch from the cyclone station, it cannot be directly dried, so it needs to be further dehydrated to remove most of the moisture. The starch milk is dehydrated with a scraper centrifuge. The scraper centrifuge traps the starch particles on the filter screen of the scraper centrifuge by high-speed centrifugation, and the filtrate is passed through the filter screen to achieve the purpose of dehydration. Since the particle size of rice starch is very small, some starch will be discharged with the filtrate when passing through the filter screen or the formed filter cake. Therefore, it is necessary to add a set of recovery cyclones to recover the small-granular starch, and the recovered starch still enters the The starch milk is temporarily stored in the tank, and the filtrate is directly discharged or enters the process water tank, and still enters the cyclone to wash the starch.

9. The dehydrated wet starch is scraped off the formed filter cake by a scraper centrifuge scraper, and the scraped filter cake enters the wet starch temporary storage hopper for temporary storage. It is sent to the air dryer to dry the starch.

10. The dehydrated starch cake is conveyed to the feed port of the air dryer through the conveyor belt, and then enters the lifter through the feeder. The heat source of the airflow dryer is a steam heat exchanger. The wet starch is heated by hot air, and the water is evaporated. After drying, the starch is separated from the air in a set of cyclones. The bottom of the cyclone separator is directly connected to the silo, and the lower part of the silo is sealed with an air shutoff device. After leaving the cyclone, the moist air is discharged into the atmosphere through the exhaust fan. The starch coming down from the air shutoff device enters the circular vibrating screen, and the starch is sieved to remove the larger solids and ensure the fineness of the product. The sieved refined starch was manually bagged into 25 kg of commercial starch. The starch after weighing and sewing is directly put into storage.

11. Like starch treatment, the protein solution separated by the cyclone station enters the disc centrifuge for further concentration, and the concentrated protein solution needs to be treated at high temperature and high pressure instantaneously for sterilization. The treated protein solution is directly pumped by a screw pump into spray drying to dry the rice protein. The dried protein powder is packaged and put into storage.

online service

online serviceScan to wechat :